Logistics Hubs Look to the Sun to Lower Energy Costs

Logistics hubs, central facilities for distributing goods, are the heart of logistics companies. Operating these warehouses requires a lot of energy, which means high costs. But there is a way to reduce these costs: their vast, flat roofs are perfect for installing solar systems, which can play a crucial role in lowering energy expenditures.

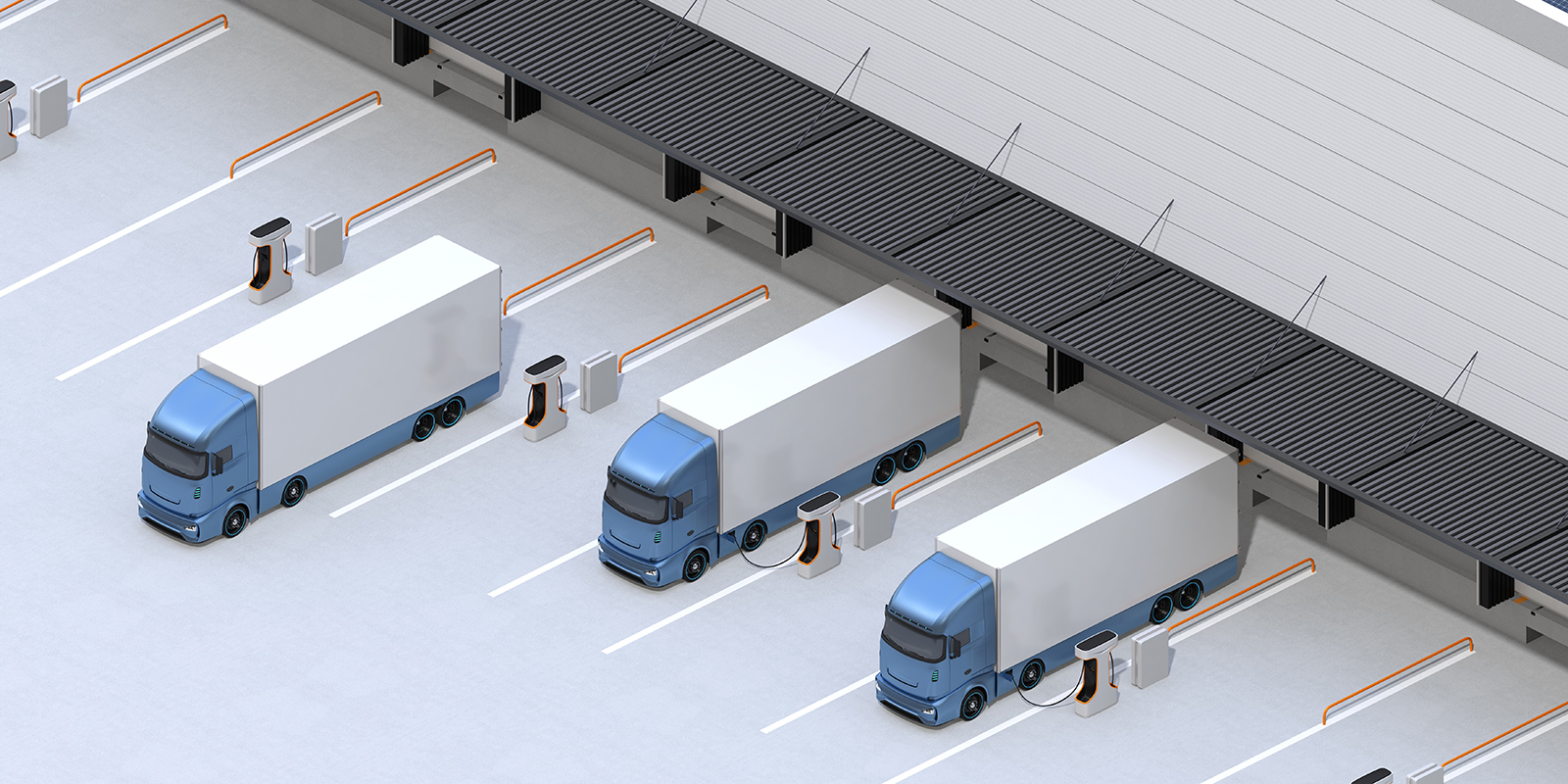

Some logistics companies are already planning for another huge challenge: transitioning company car fleets to fully electric vehicles. To achieve this, rooftop solar alone is not enough. A new smart energy model will need to combine PV production with onsite e-fleet charging and full energy management. Logistics hubs adopting this type of solution could play a central role in advancing sustainable supply chains.

Logistics Hubs Go Green for a Better Bottom Line

Surging energy prices, extreme weather, regional conflicts and other world events have raised uncertainties about future energy supply. This has had a direct impact on logistics companies, and the task of managing energy consumption in distribution warehouses is becoming increasingly complex.

In addition, the rise of eCommerce retail sales, which nearly doubled between 2019 and 2020 (a trend that that will continue), has increased package deliveries, and, consequently, transportation emissions.

A study by Coyote Logistics, which included 250 global shippers across various industries, revealed that 81% of companies believe that to achieve success, their supply chains must play an integral role in owning sustainable initiatives across their networks.

A DHL survey of U.S. consumers in May 2021 found that the majority, 60%, were willing to pay more for environmentally friendly products or services. Fifty four percent stated they put more trust in a company based on public commitments to environmental sustainability. The survey results reflect the influential role that supply chain sustainability will play in the competitiveness of eCommerce businesses in the future.

Logistics companies are also being pressured by investors and regulators to achieve more aggressive ESG goals. This is driving them to find smart renewable energy management solutions, which will become an essential component in reducing the carbon footprint of supply chains.

Many logistics companies are already moving to alternative energy sources to reduce their energy costs and dependence on the grid and to ensure uninterrupted operations. According to a report by the UK Warehousing Association, the warehouse sector in the UK could generate ~13.8 TWh of renewable electricity per year, transforming the sector from net consumers to net producers.

In the U.S. developers lag their counterparts in Europe in constructing sustainable warehouses and distribution centers. Nevertheless, American companies are taking steps to make their warehouses more energy efficient by turning their rooftops into solar farms that can power the building’s operations. These buildings, with typically large, open interiors devoted to storage and only small office areas, appear to be easier to turn green than other real estate. They usually require a moderate amount of energy, compared with more densely occupied structures such as office buildings or hotels.

Typically, non-refrigerated warehouses adopting conventional solar solutions consume no more than 10-20% of the energy they produce - for lighting & HVAC. This means that most of the produced energy is wasted, unless it is sold to the grid. However, it could also be used for powering e-fleets or sold to nearby businesses that cannot produce their own energy.

Safeguarding Warehouse Work Environments Below the Roof

Another important solar consideration for logistics companies is how to maintain a safe work environment below the roof when so much power is being produced above. Take the example of a leading Italian furniture manufacturer with a 36,000 square meter logistics hub. A SolarEdge smart energy system was chosen for their rooftop installation covering approximately 5,000 square meters.

Several factors played into the decision to install SolarEdge. The company wanted to address the sharp rise in Italy’s electricity prices in 2021-2022 and reduce reliance on the grid. In addition, since the roof was shaded by electrical wires, maximizing energy production and lowering energy losses due to solar panel shading were extremely important.

SolarEdge Power Optimizers connected to the PV modules ensured that each panel produced the maximum amount of energy, and that underperforming panels did not affect high performing ones as is true with conventional string inverter systems. And, with SolarEdge’s Monitoring Platform, the system installers were able to accurately track energy production down to the panel level. Granular analytics and real time alerts enabled remote troubleshooting of underperforming panels, which reduced truck rolls and maintenance costs. This also provided the company with maximum system uptime, a high annual energy yield, and faster ROI.

While maximizing profitability was a primary goal for the furniture manufacturer, it was critical for them to ensure the safety of their 100+ employees, as well as inflammable merchandise and expensive machinery. The SolarEdge system, with its built-in multilayer safety features, meets the industry’s most stringent safety standards and insurance requirements. The system’s safety is monitored in real-time to mitigate potential risks. The SafeDC™ feature automatically reduces the solar arrays to touch safe levels within a few minutes whenever the grid or inverter are shut down. This enables quick intervention by service crews or firefighters and protects the facility in an emergency event. This important feature, together with embedded arc fault detection, gave the furniture manufacturer the peace of mind they needed.

Transitioning to e-Fleets will Drive Carbon Neutrality

Fleet vehicles are an essential part of daily life, transporting anything from food to clothing to just about every consumer item. Internal combustion engine (ICE) vehicles are responsible for nearly 25% of total GHG emissions.

But, as delivery truck fleets still depend on diesel fuel, the logistics sector is slow to transition completely to carbon neutrality. Still, logistics companies are starting to move towards electrifying their fleets and are increasingly setting ambitious decarbonization targets.

Interest in eTrucks across the logistics sector is growing. By 2040, 15 million EVs are expected to be part of corporate fleets in the U.S. In the EU more than 30 models of eTrucks will be available by 2040, and eTruck adoption will exceed 30 percent by 2030 across different classes.

Replacing fossil fuel-powered fleet vehicles with zero-emission EVs will be a huge step towards carbon neutrality.

Increased Supply Chain Electrification Demands PV-EV Integration

To meet growing consumer demand and tighter turnaround expectations, many logistics companies are replacing their gasoline and diesel-powered forklifts with electric ones. Many are also adding energy-efficient warehouse robots to increase production and significantly reduce their energy bills.

As part of the massive growth in the e-delivery truck market, e-fleet charging is expected to increase exponentially in the coming years. In fact, BP recently announced it is building Europe’s first public corridor for ultra fast charging of e-trucks along a busy freight route stretching 600km across Germany.

Some companies might consider adding solar storage to charge e-trucks after sundown. Or they may opt for bi-directional use, by discharging solar power stored in the truck’s battery to the building (V2B). Alternatively, this power could be injected and sold to the grid (V2G) or to neighboring businesses for additional revenue. Later, to better utilize their parking structures, solar carports could be installed and connected to EV chargers, for use by employees and visitors.

A Sunny Forecast for Supply Chains

All of this increased electrification required by logistics centers will drive up energy expenditures; solar energy is the obvious solution to enable more efficient operation that reduces OPEX while complying with government and corporate GHG reduction goals.

SolarEdge’s scalable PV solutions, in particular, enable businesses to build a sustainable energy foundation that can grow as their needs evolve. By taking advantage of an end-to-end ecosystem which has as its core smart energy management, enterprises will be able to utilize solar power produced on the roof in a myriad of new ways that will guarantee sustainable supply chains and contribute significantly to a cleaner environment.

Similar Articles

Add new comment

Comments